Pallet Storage Rack – How to Buy, Size, & Select Pallet Racks

About Selective Pallet Racking Systems

Selective Pallet Racking is by far the most common and versatile type of warehouse storage rack. It is what is typically thought of when the need arises for industrial type storage racking

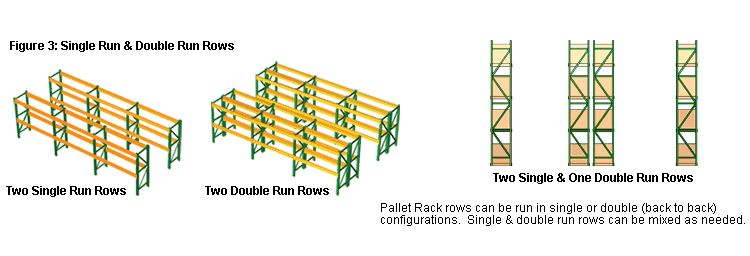

Selective racking is constructed as a single deep design, meaning that it requires an access aisle to reach each single pallet load. Density is low. Selective racking offers high accessibility to every pallet, as well as smartly utilizing the available vertical space. Arranged either in single rows or with the back of one row to the back of the other, each space of the rack can be utilized as a single SKU facing, offering the ability to mix product.

Pallet Rack Systems Guide

Pallet Rack Shelving Systems - Brands & Styles to Choose From

Listed below are some of the most common brands and types of warehouse pallet racking found today. If you have a rack style or brand not on this list, please contact us at (320) 485-4974 (direct sales line) or (800) 598-5532 and we'll be happy to help you identify it.

- Amerak

- Blackstone

- Bulldog

- Burtman

- Clymer

- Dexion

- EMI

- Excel

- Frazier

- Frick-Gallagher

- Hannibal

- Hiline

- Husky Rack and Wire

- Interlake Mecalux

(New & Old Style)

- Inca

- J-Hook

- Jarke

- Keneco

- Keystone

- Kingway

- Konstant

- Lodi

- Mecalux

- Meco

- Meco-Omaha

Pallet Rack Beams and Uprights

All selective rack is made from component pieces that are usually priced & purchased separately or may be purchased as a kit with all components included.

Pallet Rack Uprights

Uprights (also called frames, or less commonly, legs) are the support columns that hold up individual shelves in a section of rack. Pallet rack uprights form the ends of what are commonly known as 'bays' of pallet racking. Each pallet rack bay must have at least two uprights, however if multiple bays will be placed in a row they may share uprights (see figure 1 below).

Pallet Rack Beams

Beams are used to create the actual 'shelf levels' that support loads and are held up by pallet rack uprights. Pairs of beams form each individual shelf level (see figure 1). Shelf capacity is determined by the height of the beam, length of the beam and the number of shelves per bay. Most modern beams feature end clips that attach directly to the upright without the use of specialized hardware, however there are many different brands available that feature unique designs (see section on selective pallet rack brands).

Pallet Rack Assembly - Putting it all together

Now that you're familiar with the individual components, let's take a look at configuring a rack installation that's right for you.

Step 1: Size the product

The first step in determining what is needed is to size the product to be stored. The product's width, depth and height are important to know, however you must also include the height, depth and width of your pallet if you are using them (see figure 2). In addition to the size of the product, the maximum weight of the product must also be determined. These measurements are key to determining the correct rack for your needs.

Step 2: Determine Rows & Bays

Most often, static racks are configured in rows to make maximum use of available space. Rows can be configured in single or double (back to back) runs (see figure 3). The number of rows created will be determined by the width of the bays needed (see figure 1).

Determining the width of the bays is accomplished by using the product measurements taken in Step 1. A good rule of thumb is to add 6" to the width of each load to get overall bay width (also beam length - see below.)

For example, if the product width is 42" and is to be stored as two pallets per shelf, this is the correct equation: (42+6) x 2 = 96" wide bays. To determine the depth of your

uprights, subtract 6" from the depth of the product to allow the proper pallet overhang. For example, if the pallets are 48" deep, subtracting 6" gives an upright depth of 42".

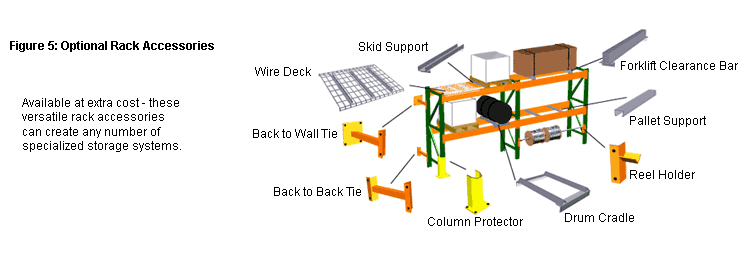

This overhang is adequate to insure that the weight of the product will be evenly distributed on the beams however, a lesser overhang is allowable as a function of aesthetics. If this is the case be sure that the pallets are in good condition. In this situation we would also recommend the use of additional supports, such as Pallet Supports or Wire Decking (see figure 5 below).

As mentioned above, the beam length will be the exact same as the width of the bays. The length of beams is always measured from the insides of the upright frames.

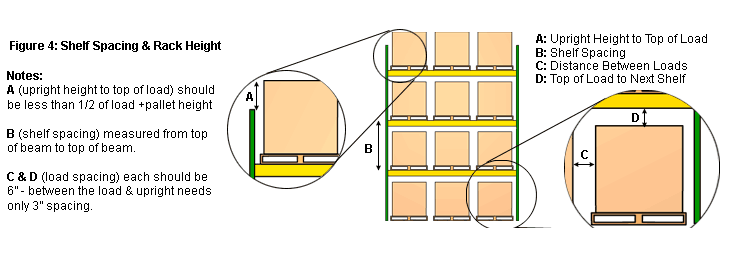

Step 3: Determine Warehouse Shelf Spacing & Overall Rack Height

To get the overall rack height, again use the load measurements taken at the beginning. To each load, add 6" to get the distance between shelves. The beam height will also need to be accounted for here and a rough estimate of 4", 5" or 6" per shelf level (depending on shelf capacity needed) will leave enough room for the beams. An equation to use for this height would read as follows:

Formula to Determine Overall Rack Upright Height:

(Pallet Load Height + 6") x number of Pallet Storage Shelf Levels) +

([4", 5" or 6"] x number of Shelf Levels) = Upright HeightPlease note - The top of the upright should be more than 1/2 the height of the pallet + load to prevent loads from tipping over and falling off the rack. The bottom of the top load should never be at the top of the upright.

Other items to take into account when determining the overall rack height are the overall height of the ceiling, sprinkler system, lights and any other obstructions. Make sure to also account for the maximum reach of the lift truck that will retrieve the pallets. Also of note when determining aisle width is the turning radius of the lift truck.

Step 4: Consider Pallet Rack Accessories

A Note About Wire Decking

Wire Decking is typically used as a "fail-safe" when used in conjunction with static pallet rack. If you have pallets loaded with loose boxes, cartons or other materials the decking will act to catch items knocked off of the pallet to prevent injury to persons on the ground (provided the items are no smaller than the deck's mesh size). Wire decking will also not prevent an item from falling off the front or back of the racking system. Although wire decking can be used as a "shelf level" to hold assorted goods, please note that most wire decks are NOT RATED FOR POINT LOADING. What this means is that if a deck's overall capacity rating is 2,000 lbs, the deck will

support a 2,000 lb load evenly distributed over the entire surface of the deck. The palletized load must still be entirely supported by the front and rear pallet rack beams.

Pallet Rack Identification Guide

There are many dozens of pallet rack types available in the U.S. alone. SJF has compiled a list of the most common brands (or makes) with photos in a handy guide.

View the Pallet Rack Identification Guide.

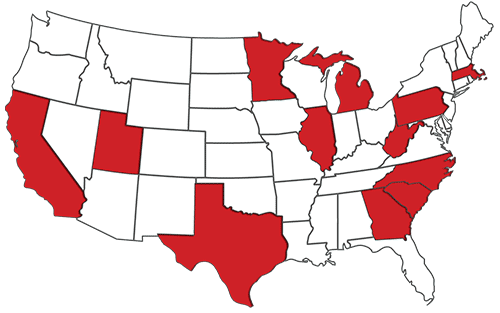

Looking for "Pallet Rack Near Me?"

Pallet Racking Systems Shipping Locations - We Ship NATIONWIDE

SJF Material Handling Inc. ships warehouse racking systems from multiple locations:

- California

- Georgia

- Illinois

- Massachusetts

- Michigan

- Minnesota

- North Carolina

- Pennsylvania

- South Carolina

- Texas

- Utah

- West Virginia

- Ontario, Canada