Story Highlights

- Four wire divider options explained to help keep pallet rack systems safe, organized, and compliant with flue space regulations

- Easy-to-install divider styles like hanging, clip-in, and upright spacers provide flexible, scalable bin storage

- Improve rack safety and inventory accuracy by using wire deck dividers that meet code and reduce risk of obstruction

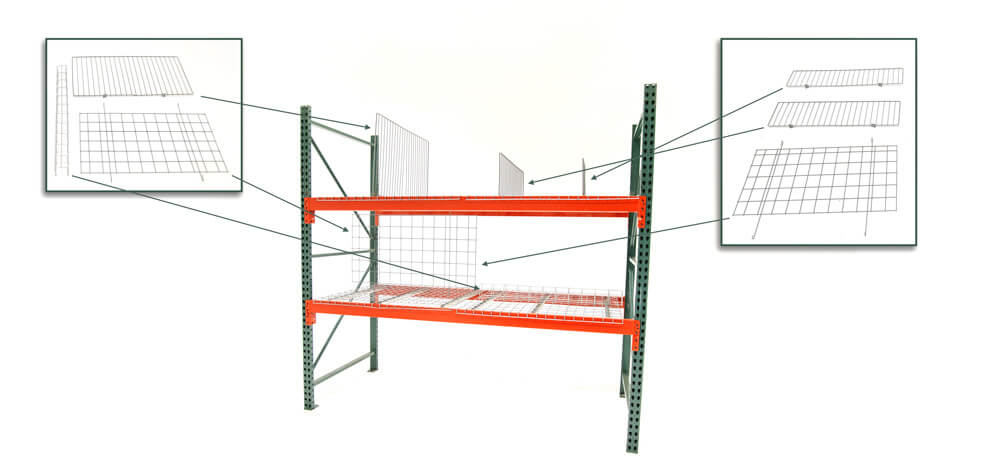

Wire deck dividers are commonly used for two purposes:

- To create and ensure compliance with flue spaces required within rack systems, and

- To create and separate bins in a pick area.

Creating a defined space ensures that products to not impede in flue spacing, and that products are always in the correct bin for inventory. There are four common methods of utilizing dividers in pallet rack systems.

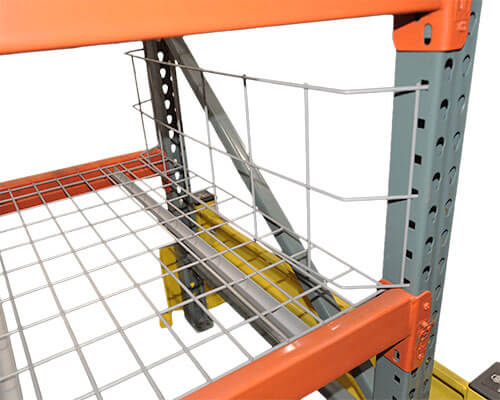

1. Hanging Dividers

These dividers hang either front-to-back or left-to-right from the decking above it. The wire extends past the deck below it to keep the divider in place.

These dividers are easily moved, allowing flexibility when frequent reconfiguration is required.

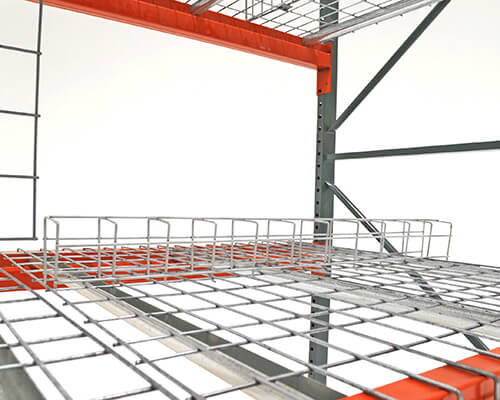

2. Clip-In or Snap-In Dividers

These dividers have hooks or clips that snap into the wire deck that it sits on. These dividers do not require an additional deck for hanging.

These are a great option to create multiple bins on a single shelf.

3. Flue Spacer Divider

These dividers snap into the wire mesh deck, creating a flue space where cartons cannot be placed. They can also be used as a back stop to ensure cartons remain compliant for pallet rack flue safety.

4. Upright Flue Spacer

These dividers clip into the upright, creating a barrier between the upright and storage bin. This barrier is required in many areas for flue space compliance.