In my time in direct sales, I have uncovered 2 simple truths. The first one, I had to learn. The second is a truth that I’d like my customers to learn.

First and foremost though, project sales is harder than it looks. And by hard, I mean time consuming. Don’t get me wrong, the lead opportunities are great at SJF. There’s no shortage of customer interest & quote requests. Whether it’s by phone or email, when I do speak with customers they don’t always know how to put into words what they envision in their minds. The back and forth translation of needs & wants takes a lot of time. There are days where I feel like a child on an Easter egg hunt with an eye patch and a broken hip. It’s not that we don’t have the equipment, (we have loads of equipment!) it’s just that with used equipment, having the exact material at the exact time a customer needs it can be a challenge.

This leads me to the first truth:

TRUTH 1) You can do everything right, and there still may be something that goes wrong.

This is the number one reason for customer follow-up. If you can catch errors quickly, you can start on a solution before the customer even knows there was a problem, and you can then begin to make it right. In my case, thankfully the customer was more than understanding and the vendor was very prompt in rectifying the error.

I am a list maker. I have the mother of all worksheets that’s currently tracking all of my progress, current orders, lost orders, pending issues, etc. I analyze this list often to ferret out hidden trends. I was just looking over my lost orders recently and I found the second truth – this one is for my customers.

TRUTH 2) It’s going to be sold if you don’t nab it now.

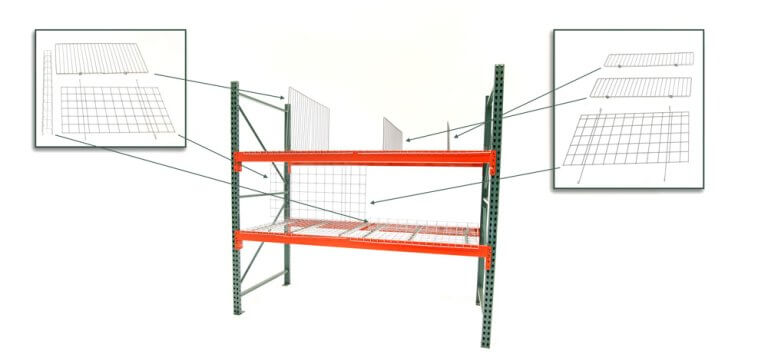

On a daily basis, we have thousands of dollars of pallet racking being put onto trucks and shipped to customers across the United States. Used teardrop pallet rack is a HOT COMMODITY. When I tell my customers, “These will not be here long. They are hard to find used and are a very popular size,†I expect them to heed my warning…but they don’t always. They think I’m using a sales ploy, and several have had to find out the hard way that it’s the cold hard truth.

For example, one day I had three signed quotes. I had to re-address each one because the customers took too long to return a signed order. When I finally did receive the orders, the material I had quoted (1 day prior) was already gone. It’s times like these that I’m grateful SJF has a lot of other racking to offer in substitution. In the end, I found equivalent racking for each of these customers, and all were happy, however I still find many customers want a quick quote and are not so quick to give you a final decision.

This is a great blog. Excellent content.

Thank you so much Manufacturing Marketing Innovation 2013 for the positive feedback.

Hey R – that’s a great set of lessons for both sides of the sales equation. I know you’ll keep the customers happy, always do the best for them, and you’ll do great in your role. Keep smiin’

M

Great blog Rhonda!