Story Highlights

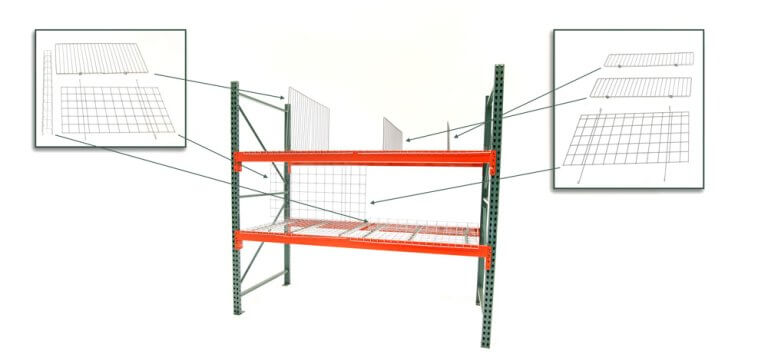

- Stretch Your Warehouse Vertically with Teardrop Racks – Leveraging teardrop pallet racking lets you stack higher, reduce aisle space, and double your storage efficiency, all without expanding your footprint or sacrificing access.

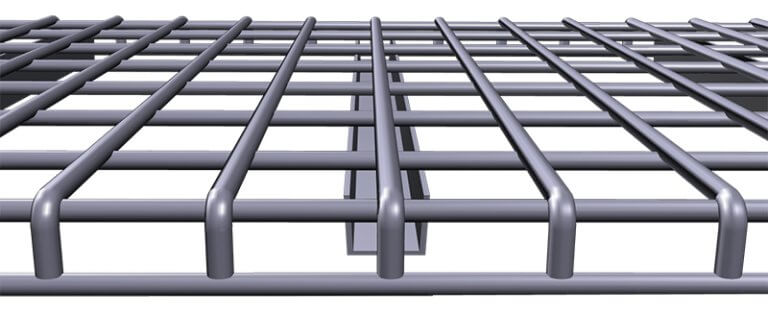

- Boost Safety and Flexibility with Wire Decking & Adjustable Beams – Add wire decking to reinforce load support, improve visibility, and keep fire suppression systems clear. Pair that with adjustable beam levels for zone?specific storage that adapts as your inventory shifts.

- Amp Up Capacity with Double-Deep Racking (Know Your Reach-Forklift Needs) – Double-deep configurations cut aisle needs and increase density, but keep in mind they often require deep-reach forklifts. It’s a smart trade?off when paired with the right equipment.

If you’re looking to optimize your warehouse space, pallet racking is the answer. This system not only enhances your storage capabilities but also streamlines your operations, making your warehouse a well-oiled machine.

Pallet racking is a storage solution that allows you to stack materials on pallets (or “skids”) in horizontal rows with multiple levels. It’s a highly efficient way to store inventory, as it maximizes vertical space and provides easy access to stored goods. Whether you run a small business or manage a large distribution center, pallet racking can transform your warehouse’s capacity and functionality.

Types of Pallet Racking Systems

Understanding the different types of pallet racking systems is key to choosing the right one for your warehouse. Here’s a look at some of the most common options:

- Selective Racking: This is the most common type of pallet racking. It offers direct access to each pallet, making it ideal for businesses with a wide variety of products. It’s perfect for high turnover products where quick access is essential.

- Drive-In/Drive-Through Racking: This system is designed for high-density storage. It allows forklifts to drive directly into the racks to retrieve pallets. Drive-In is best for last-in, first-out (LIFO) inventory systems, while Drive-Through is suitable for first-in, first-out (FIFO) setups.

- Push Back Racking: This system uses a series of nested carts that operate on a slight incline. When a pallet is loaded, it pushes the previous pallet back. This is ideal for businesses that need to store multiple pallets of the same product.

- Pallet Flow Racking: Also known as gravity flow, this system uses a sloped design that allows pallets to roll forward when the front pallet is removed. It’s great for FIFO inventory management.

Benefits of Pallet Racking

Pallet racking offers numerous advantages that make it a preferred choice for warehouses around the globe. Here are some of the key benefits:

Space Optimization

One of the most significant advantages of pallet racking is its ability to maximize your warehouse space. By utilizing vertical space, you can store more inventory without needing to expand your physical footprint. This not only saves money but also allows for a more organized storage area.

Improved Inventory Management

With pallet racking, you gain better control over your inventory. The system allows for clear labeling and easy access, reducing the chances of misplaced or lost items. This is particularly useful in large warehouses where keeping track of inventory can be challenging.

Increased Safety

Safety is a top priority in any warehouse, and pallet racking systems are designed with this in mind. They are sturdy and built to withstand heavy loads, reducing the risk of accidents. Additionally, by organizing products more efficiently, you minimize clutter and create safer walkways for employees.

Enhanced Productivity

Pallet racking systems streamline the process of retrieving and storing inventory. With organized storage and easy access, your warehouse staff can work more efficiently, reducing the time it takes to fulfill orders and increasing overall productivity.

Choosing the Right Pallet Racking System

Selecting the right pallet racking system depends on several factors, including the size of your warehouse, the type of products you store, and your inventory management strategy. Here are some considerations to keep in mind:

Assess Your Storage Needs

Begin by evaluating the types of products you handle and your storage requirements. Consider factors such as product size, weight, and turnover rate. This will help you determine which type of pallet racking system best suits your needs.

Consider Future Growth

It’s essential to plan for the future when selecting a pallet racking system. Choose a system that can accommodate your business’s growth and adapt to changing storage needs. This ensures that your investment remains valuable over the long term.

Evaluate Your Budget

While pallet racking systems are a cost-effective storage solution, prices can vary depending on the type and complexity of the system. Determine your budget and explore options that offer the best value for your money without compromising on quality and safety.

Installation and Maintenance

Once you’ve selected the right pallet racking system, proper installation and maintenance are crucial to ensure its longevity and performance.

Professional Installation

For optimal safety and efficiency, it’s advisable to have your pallet racking system professionally installed. Experienced installers will ensure that the system is set up correctly and complies with safety standards.

Regular Inspections

Regular inspections are essential to maintain the integrity of your pallet racking system. Look for signs of wear and tear, such as bent beams or damaged uprights, and address any issues promptly to prevent accidents.

Employee Training

Ensure that your warehouse staff is trained in the proper use of the pallet racking system. This includes safe loading and unloading practices, as well as understanding weight limits and load distribution.

Conclusion

Pallet racking is a game-changer for warehouses looking to maximize space and improve efficiency. By choosing the right system and maintaining it properly, you can enhance your inventory management, increase safety, and boost productivity. Whether you’re a small business owner or manage a large warehouse, investing in pallet racking is a smart decision that will pay off in the long run.