What is a Used Flexible Gravity Conveyor?

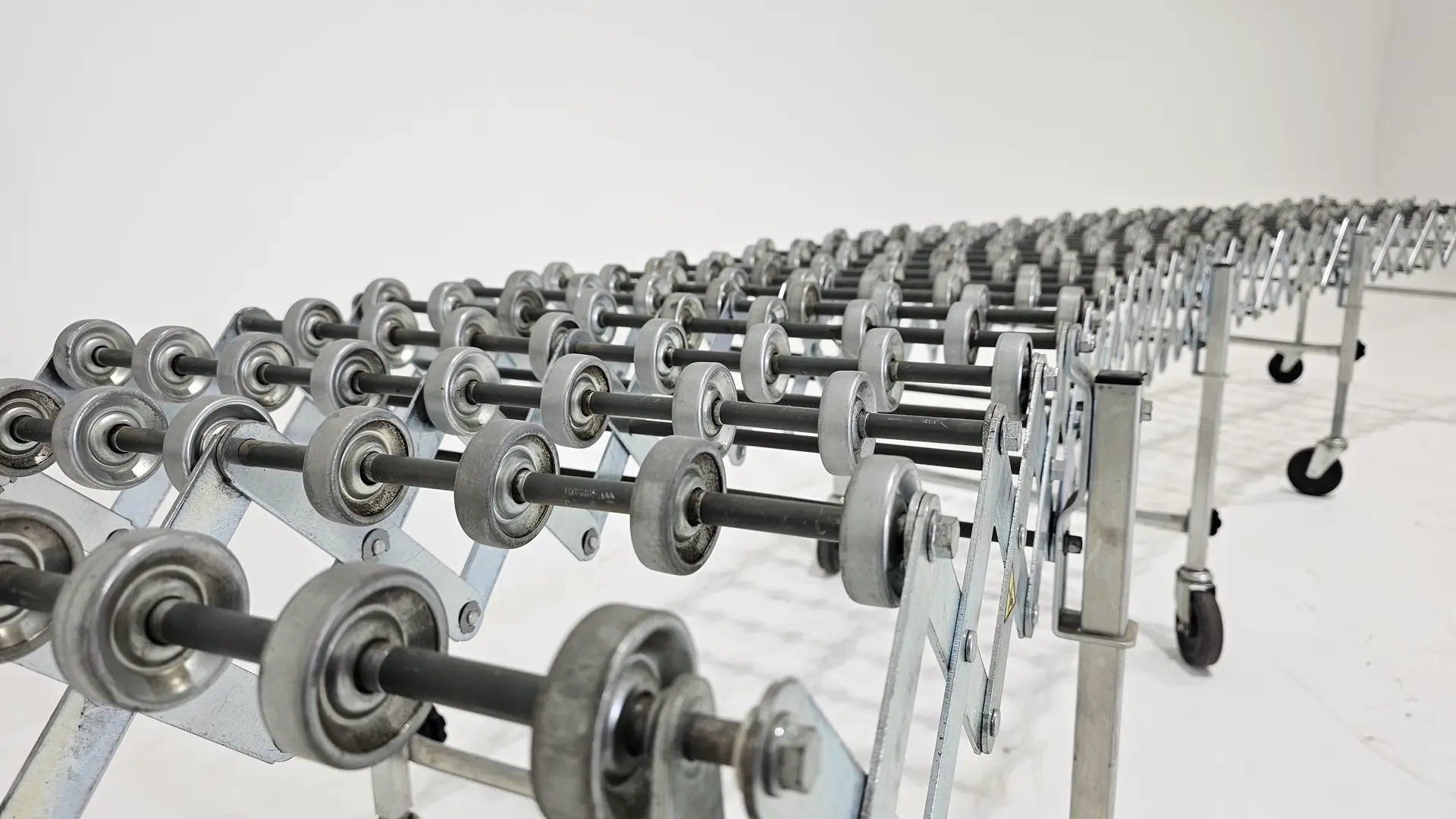

A used gravity flex conveyor is a versatile and cost-effective solution for material handling that adapts to changing workflows. These conveyors are designed with flexible frames and skatewheels or rollers that can expand, contract, and curve, making them perfect for dynamic environments. As a gravity-powered system, they require no motors or electricity, relying instead on slight inclines or manual force to move items efficiently.

Gravity flex conveyors are ideal for transporting a variety of items, including boxes, cartons, and other flat-bottomed products. Their modular design allows for easy reconfiguration, making them suitable for temporary setups or permanent installations in warehouses, distribution centers, and manufacturing facilities.

How Do Gravity Flex Conveyors Work?

Gravity flexible conveyors use their adjustable frame and wheels to create a transport path tailored to your needs. Their portability and flexibility make them ideal for temporary setups or spaces where traditional conveyors are impractical. Items are typically moved down a slope or manually pushed, providing smooth and efficient handling for boxes, cartons, and other flat-bottomed items.

What Types of Flexible Gravity Conveyor Are Available at SJF?

SJF offers a wide range of used flexible gravity conveyors, including popular brands like NestaFlex, BestFlex, and PowerFlex. These conveyors come in various lengths, widths, and configurations to suit different applications. Whether you need a straight conveyor, a curved model, or a combination of both, SJF has the right solution for your material handling needs.

Our used flexible gravity conveyors are thoroughly inspected to ensure optimal performance and reliability. We also offer a selection of new flexible conveyors for those seeking the latest technology and features in our online store.

Used gravity flex conveyors are commonly utilized in warehouses, shipping docks, and distribution centers. They excel in applications where adaptability is key, such as loading and unloading trucks, connecting workstations, or navigating around obstacles in tight spaces. Their ability to collapse for storage and expand when needed makes them a practical solution for operations with fluctuating demands or limited space.