Gravity Conveyor: Economical - Cost Effective - Versatile

What is a Gravity Conveyor?

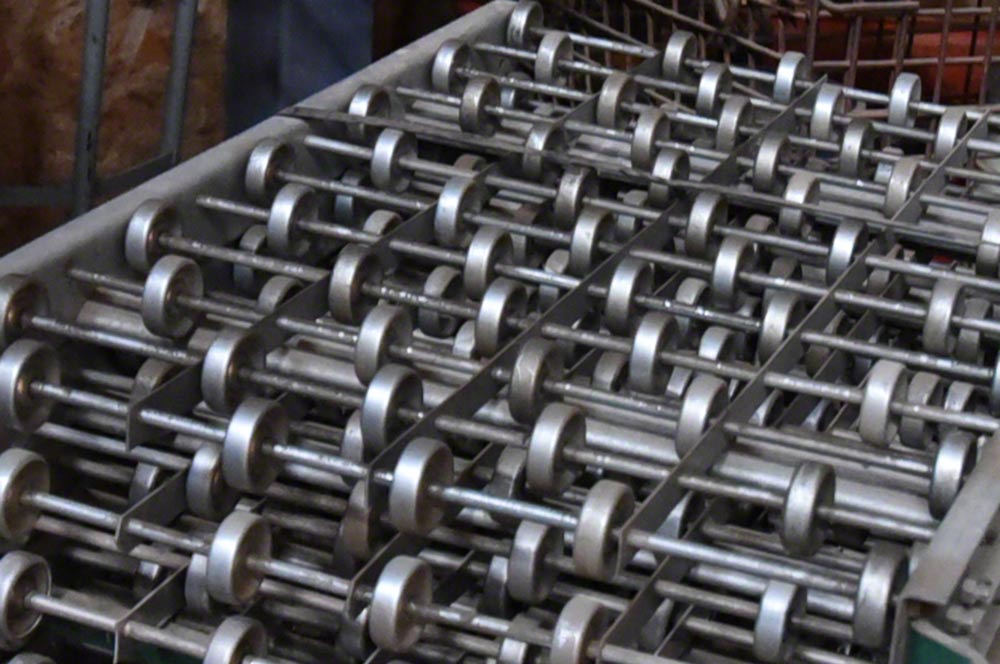

A gravity conveyor is a type of conveyor system that moves materials without the need for electrical or motorized power. Instead, gravity is used to move items down a slight incline or across a series of wheels or rollers. This simple yet effective method of material handling provides a low-maintenance, cost-effective solution for transporting items such as boxes, cartons, pallets, and containers. Gravity conveyors are available in two main styles: roller conveyors and skatewheel conveyors, each designed to handle different types of loads and environments.

How Gravity Conveyors Work

Gravity conveyors rely on either an incline or manual force to move items. The conveyor's slope allows products to slide down without extra power, making it ideal for transporting goods from one level to another, such as in loading docks or assembly lines. In many cases, items can be manually pushed along, especially with lightweight or smaller items. Roller conveyors use cylindrical rollers to support and move the load, while skatewheel conveyors use small, closely-spaced wheels for smoother rolling and better maneuverability around curves.

Applications of Gravity Conveyors

Gravity conveyors are commonly found in warehouses, distribution centers, manufacturing plants, and shipping facilities. They are particularly useful for loading and unloading trucks, guiding items through sorting areas, and transferring goods between workstations. In pick-and-pack areas, gravity conveyors help improve productivity by reducing the need for workers to carry items manually. They can be used in both permanent and temporary setups, and they are often portable, making them easy to adapt for changing workflows or seasonal demands.