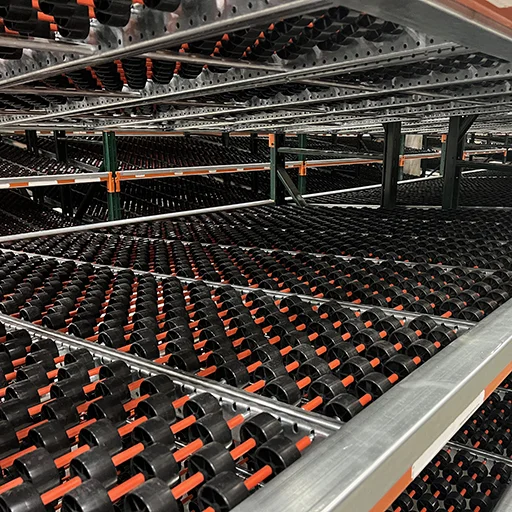

Carton Flow Rack Storage System Overview

Carton flow rack integrates gravity rollers directly into the shelf structure, featuring shelves with a downward pitch for seamless gravity flow from the in-feed side (rear) to the pick side (front). This design enhances full case or split case picking, providing increased SKU visibility, stock rotation, and accessibility advantages.

Utilizing variable shelf depth, our gravity flow rack enables denser product storage within a single bay compared to standard static racks, resulting in reduced restocking time. With separate picking and restock aisles, processes remain distinct, minimizing interference and congestion. Our carton flow system ensures FIFO (First In, First Out) inventory control and is suitable for a diverse range of products.