Explore New and Used Pallet Racking for Sale to Optimize Your Storage

If you're looking to streamline operations and get more out of your warehouse, our warehouse racking solutions are engineered to help you do just that. From growing e-commerce hubs to established distribution centers, we provide high-quality pallet storage racks that boost efficiency, improve organization, and make better use of your vertical space.

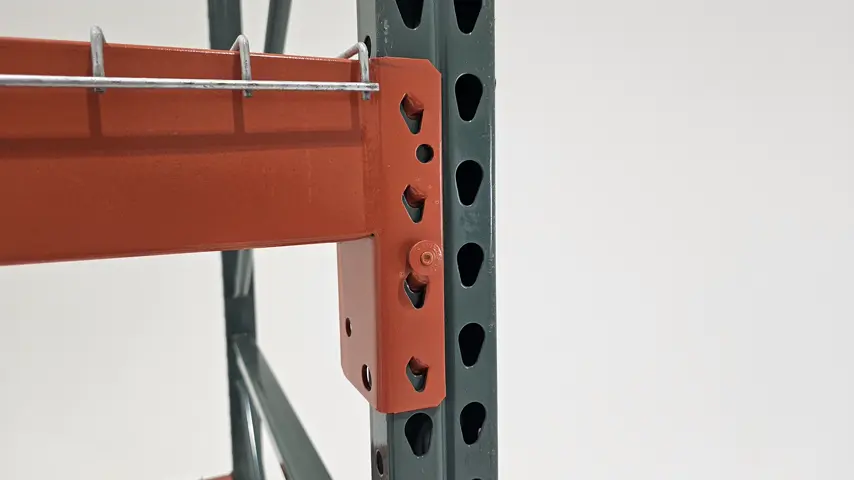

We carry a wide selection of pallet racking for sale, including both new and used pallet racking to meet your operational needs and budget. Whether you're after selective racking for quick access to diverse SKUs or need a high-density pallet storage system like push-back or drive-in racking, our team will help you find the right fit. Our warehouse racking systems are built tough for industrial use, adaptable for expansion, and available in custom configurations.

With decades of industry experience, we’ve helped businesses across manufacturing, logistics, food service, and more implement industrial pallet racks that make a real impact. From design and layout to installation and permitting, we support you at every stage—ensuring your pallet storage system works seamlessly within your operation.

Disorganized storage and underused space cost your business time and money. The right warehouse racking system transforms cluttered floors into structured, scalable storage—speeding up access, protecting inventory, and driving long-term growth.

Whether you're upgrading, expanding, or replacing existing systems, explore our full line of new and used pallet racking today. Let us help you design a durable, efficient storage solution tailored to your business goals.