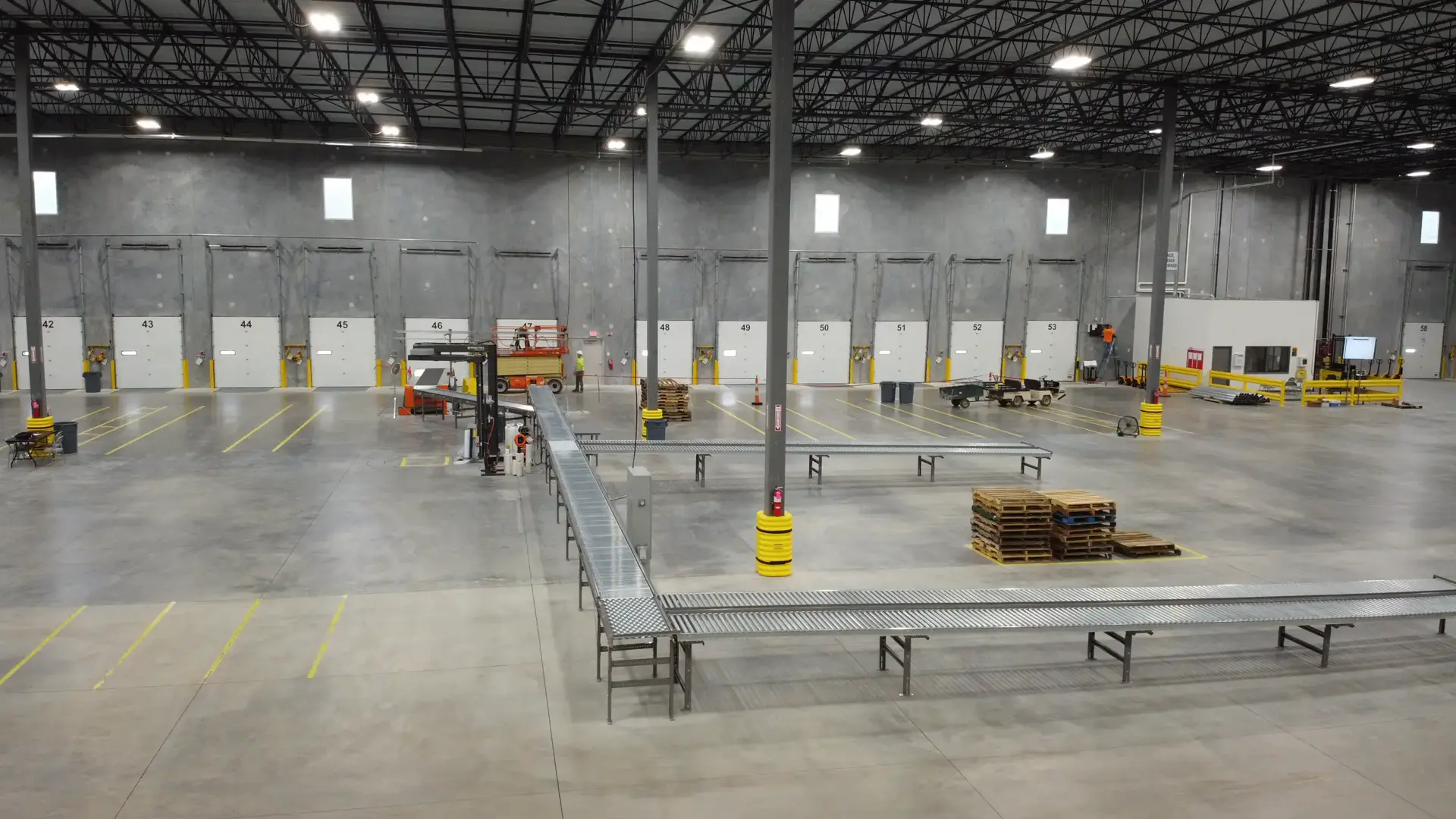

A 3PL customer, who was opening a new fulfillment center for a home goods retailer, was in need of an efficient way to unload and palletize inbound containers for receiving inventory to stock. The majority of containers contained 6 skus or under, while a small percentage could contain higher numbers of skus.

For containers with 6 or less SKUs, SJF designed a system to upload a customer ASN and populate the incoming SKUs to the receiving WCS. The HMI allowed users to select a sort lane for the SKUs to sort to. This simplified the pallet build process as the product was pre-sorted. The inbound containers were scanned utilizing a 6 sided scan tunnel and sorted to the selected lane for pallet build.

Containers containing more than 6 SKUs were unloaded to a manual scan. More down lanes were designed to accommodate the larger pallet count.