Reliable Service for Safe, Productive Operations

Even well-built systems need care over time. We provide repair and maintenance services that support both new and used equipment in warehouses of all sizes. Because SJF supplies new, used, and refurbished systems, our technicians are familiar with a wide range of brands and components. This helps us spot problems early and recommend practical solutions before they grow into larger issues.

Conveyor Repairs and Mechanical Service

For conveyors, we handle mechanical repairs such as belt replacement, roller changes, motor and gearbox service, and frame adjustments. If sections of conveyor are worn or outdated, we can rebuild them and extend their life without requiring a full replacement. Our teams understand how line flow, elevation changes, and transitions affect long-term performance, so repairs support the overall system instead of treating isolated problems.

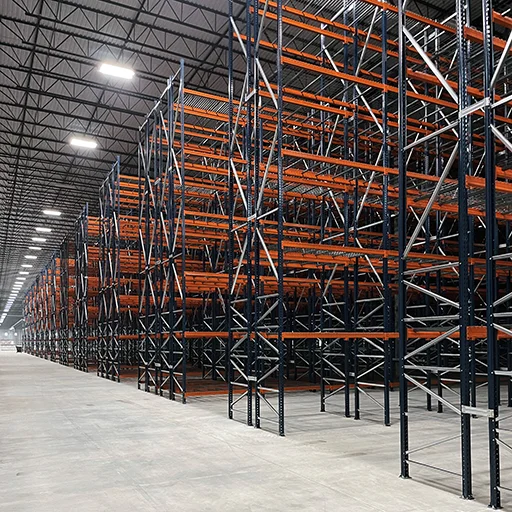

Rack Damage Assessment and Structural Repair

Rack damage is a common concern in busy facilities. We inspect frames, beams, anchors, and connections for impacts or stress that may compromise safety. When repairs are needed, we can replace damaged components, reinforce key areas, or install rack repair kits designed to restore structural strength. Our approach helps bring the system back to proper working condition while keeping you aligned with rack safety standards.

Replacement Parts and On-Hand Stock Support

We provide replacement motors, belts, bearings, rollers, and other components for many system types. Because SJF maintains a broad inventory of new and used equipment, we often have fast access to hard-to-find parts that help reduce downtime. When possible, we help you build a small on-site stock of critical items so minor issues can be addressed right away.

For select conveyor brands, our customer portal makes it easy to order parts online. This helps your team stay supplied with the components needed to keep your equipment running smoothly.

Preventative Maintenance Programs

Planned maintenance is one of the most effective ways to avoid costly breakdowns. Our maintenance programs include visual inspections, mechanical checks, lubrication, adjustments, and reporting on any issues that need follow-up. These visits give you a clear view of system health and help you plan repairs or upgrades before they impact uptime.

Support for Older and Discontinued Equipment

Many facilities rely on older or discontinued systems that still perform well but need occasional care. Our technicians have experience working with legacy brands and equipment that may no longer be supported by the manufacturer. We can often repair or refurbish these systems to extend their life and help you manage costs while planning future changes.