Cantilever Storage Racks

While this guide is meant to assist you in choosing your rack, it is still beneficial to consult with one of our professional solutions specialists. They have been working with this material every day for years and are aware of ALL the tips and tricks concerning cantilever racks.

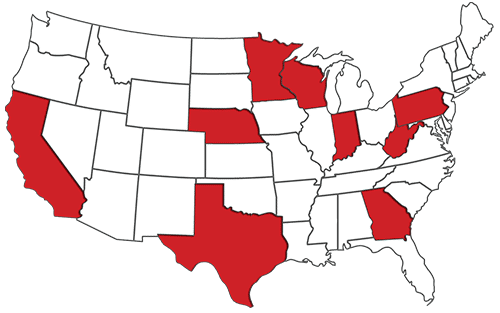

SJF is a nationwide stocking distributor of new & used cantilever racks offering 72-hour quick ship from our Minnesota and Pennsylvania stocking locations. SJF offers a wide array of models and sizes with weight capacities to meet even the most demanding requirements.

With over 20 acres of in-stock inventory of used storage racks, SJF is a go-to source for some of the most popular brands of cantilever racks including:

Please feel free to call us at (320) 485-4974 (direct sales line) or (800) 598-5532 to discuss your planned layout.

Click here to visit the used cantilever racks and lumber storage rack page. For new cantilever rack, click here.

SJF currently has cantilever racks and other warehouse storage racks available from most every major manufacturer. These racks are in-stock and ready for immediate shipment to you. Can't find what you're looking for? Call us at (320) 485-4974 (direct sales line) or (800) 598-5532 and we can help find it!

Cantilever racks are steel shelving units with long arms that extend from metal frames used to store long, bulky or awkward materials. They are used to store items such as furniture, lumber, PVC, metal pipes, steel bar stock, plywood, steel sheets, sheetrock and even cars.

Cantilever racks are configurable in countless different ways, allowing a flexible solution to fit any type of storage needs. They can be used both indoors and outdoors and are found in warehouses and storage yards across the world as an efficient storage solution. In addition, cantilever racking can be decked to provide static storage similar to pallet racking, with the advantage that it provides easier storage and retrieval of bulky or oddly sized material than traditional pallet rack.

At SJF, you can find light duty, medium duty and heavy duty components, kits and cantilever systems in stock and ready to ship.

We can also help you find specialty cantilever systems such as cantilever lumber racks, salvage racks and cantilever supported rack with roofs.

Cantilever racks are known by many names, such as:

The storage density with cantilever racks can be very high if you plan out how you will use it efficiently, but generally cantilever rack's flexibility makes it a very popular storage solution with near immediate return on investment.

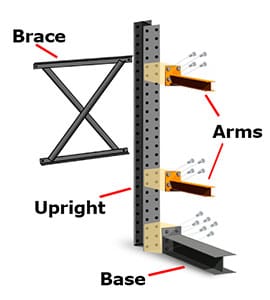

Cantilever rack uprights are the vertical support columns that are the backbone of the cantilever rack. Cantilever bases and arms attach to the uprights to complete the cantilever rack system.

Uprights are available in single or double sided configurations. Single sided cantilever racks allow material to be stored on the front side only. With double sided uprights, material can be stored on both the front and back sides of the rack.

CAUTION - NEVER put arms on the back side of single sided cantilever rack. Even if the upright has holes to hold arms on both sides, this is a very dangerous practice and should be avoided at all costs.

Cantilever rack arms extend out from the uprights to create the levels that are used for storage, similar to pallet rack beams. The arms are typically adjustable on the upright to create shelf levels of whatever height are needed. Arms can be straight or inclined to hold goods that may roll off. Some arms even come with a "lip" that attaches to the end of the arm to prevent loads from slipping off the front of the rack.

Cantilever rack braces go between uprights to stabilize the rack laterally. Braces are not intended to hold loads and should only be used to connect and brace the uprights in a row. The braces will be the same length as the spacing between uprights.

Cantilever racks are steel shelving units with long arms that extend from metal frames used to store long, bulky or awkward materials. They are used to store items such as furniture, lumber, PVC, metal pipes, steel bar stock, plywood, steel sheets, sheetrock and even cars.

Cantilever racks are configurable in countless different ways, allowing a flexible solution to fit any type of storage needs. They can be used both indoors and outdoors and are found in warehouses and storage yards across the world as an efficient storage solution. In addition, cantilever racking can be decked to provide static storage similar to pallet racking, with the advantage that it provides easier storage and retrieval of bulky or oddly sized material than traditional pallet rack.

At SJF, you can find light duty, medium duty and heavy duty components, kits and cantilever systems in stock and ready to ship.

We can also help you find specialty cantilever systems such as cantilever lumber racks, auto salvage racks and cantilever supported rack with roofs.

Cantilever racks are known by many names, such as:

The storage density with cantilever racks can be very high if you plan out how you will use it efficiently, but generally cantilever rack's flexibility makes it a very popular storage solution with near immediate return on investment.

Cantilever rack uprights are the vertical support columns that are the backbone of the cantilever rack. Cantilever bases and arms attach to the uprights to complete the cantilever rack system.

Uprights are available in single or double sided configurations. Single sided cantilever racks allow material to be stored on the front side only. With double sided uprights, material can be stored on both the front and back sides of the rack.

Cantilever rack arms extend out from the uprights to create the levels that are used for storage, similar to pallet rack beams. The arms are typically adjustable on the upright to create shelf levels of whatever height are needed. Arms can be straight or inclined to hold goods that may roll off. Some arms even come with a "lip" that attaches to the end of the arm to prevent loads from slipping off the front of the rack.

Cantilever rack braces go between uprights to stabilize the rack laterally. Braces are not intended to hold loads and should only be used to connect and brace the uprights in a row. The braces will be the same length as the spacing between uprights.

Roll-form cantilever rack is the preferred storage rack for light and medium storage due to its bolt-less design and lighter overall weight.

Structural cantilever rack is preferred for heavier loads when storing loads that weigh 1,500 lbs. or more. Structural cantilever rack is made from hot rolled c-channel structural steel. It uses additional hardware (nuts and bolts) for assembly. It is inherently heavier, stronger and can hold heavier loads than roll-form rack. It is more impact resistant than roll-form rack.

While roll-form rack is the rack of choice for light and medium storage, structural rack is often the preferred solution for higher density applications. Structural racks are thicker and the heavier construction offers improved resistance to impact from forklifts entering and exiting the racks.

You should consider using structural racks:

Due to its heavier weight, structural cantilever rack costs more to ship than roll-form cantilever. Roll-form rack is less costly to ship because it's lighter than structural racks with the same dimensions.

Due to its heavier weight and nut and bolt connections, structural cantilever racking may take longer to install, which could affect cost. Roll-form cantilever rack traditionally installs faster due to its bolt-less connection design, which allows for a fast and easy connection of the arms to the uprights.

Eric Thovson (ET) explains what cantilever racking is and why it's an excellent solution for heavy duty storage shelving in a variety of different applications.

SJF is a nationwide stocking distributor of new & used single sided and double sided cantilever storage racks and shelving. Now offering 72-hour quick ship from our Minnesota and Pennsylvania stocking locations. SJF offers a wide array of models, sizes and arm lengths with weight capacities to meet even the most demanding requirements.

In order to have a safe, effective and efficient cantilever rack system, it is first important to think about what will be stored, the size of the load and the weight capacity necessary to support your load. These instructions will help you determine what you need.

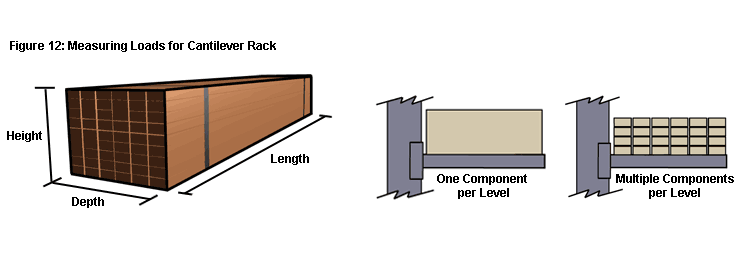

We're going to start by measuring the height, depth and length of the load. You will need to make sure that if your load consists of multiple components, you take into account the measurement of the entire unit load and not just a portion of the load. (see figure 12)

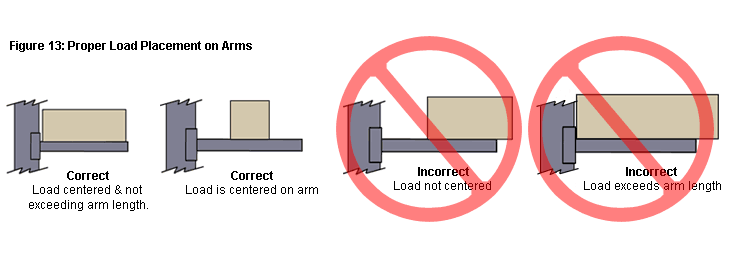

Determine the minimum arm length needed by measuring the depth of the load to be stored on the cantilever. This measurement is the minimum arm length needed for your cantilever system. Please Note - the depth of your load should not exceed the length of your arm. The rated arm capacities of cantilever rack will not be correct if you improperly load the racking. (see figure 13 for correct arm loading techniques)

Lateral spacing is the distance from the center of one upright to the center of the next. To determine the spacing between uprights, you'll need to measure the distance between the centers of the uprights. You'll also need to take into account load deflection.

Load deflection, the bowing or sagging of a load, is a very real concern when using cantilever rack to store long items. Determine the lateral spacing needed between uprights that correctly supports the load weight by watching for bowing or sagging of the load. The distance between uprights that causes minimal load deflection is the amount of lateral space needed to provide proper support.

A good method to determine the lateral spacing needed is to use blocks of wood placed on the ground. Place your load on these blocks to check for proper support. If two blocks yield too much deflection, try three - if that's too few, try four. Make sure the blocks are placed at even distances from each other. When running these tests, you must use the correct spacing method shown in figure 14. The load should overhang the end arms by no more than 1/2 of the distance from the center of one upright to the center of the next upright.

When designing a cantilever rack system, you should try to use the fewest number of arms to store your loads. However, since deflection may damage your load, you should also strive to keep deflection to a minimum.

Taking this into account, the lateral arm spacing of an 8' load supported by two arms (as in the figure below) would be 4' as this would allow for 2' unsupported on each end.

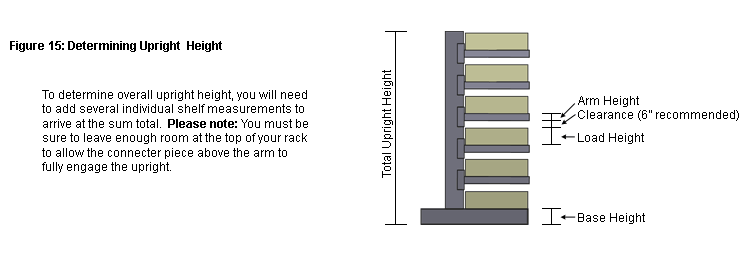

As with other rack types, to determine the necessary height for the uprights by considering ceiling height, lift truck reach and any other items that may interfere with the top of your racking. These measurements must include the actual load height and necessary clearance. This can include sprinklers, ceiling joists and lighting, among other things.

Be sure to also determine the necessary distance between levels by considering the clearance needed between the top of the load and the bottom of the next shelf. These measurements include the actual load height, the clearance between the top of the load and the bottom of the next shelf (6" is recommended), the height of the arms and the height of the base. These measurements will tell you the upright height necessary as well as the number of arms needed for the levels.

Figure 15 shows the measurements you need to arrive at the total upright height. Notice in the figure that a load has been placed directly on the base. This is not only acceptable, it is recommended and does not diminish the capacity of the upright. A commonly recommended practice is to place your heaviest load on the base because it doesn't subtract from the overall upright capacity.

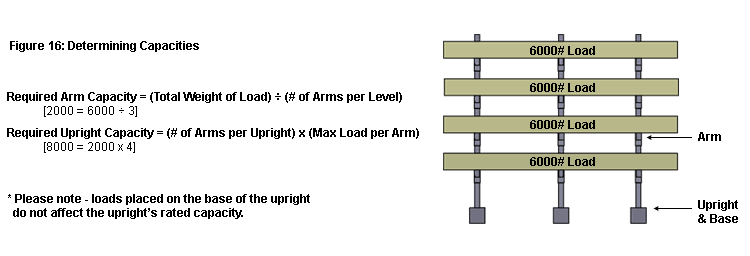

In a properly loaded cantilever rack, each arm supports an equal part of the load's weight. Determine the necessary arm capacity by first determining the number of arms needed to hold the load and divide the load's weight by that number. This number is the individual arm weight capacity. In figure 16 below, there are three arms supporting an equal part of a 6,000 lbs. load. This would give you a needed arm capacity of 2,000 lbs.

To determine upright capacity, simply multiply the number of arms per side by the load on each arm. This will give you the upright capacity. In figure 16 below, since there are four arms each holding a weight of 2,000 lbs., the required minimum capacity of the upright would be 8,000 lbs.

Please call (320) 485-4974 (direct sales line), (800) 598-5532 (toll-free) or Email Us for pricing, availability and lead times. If you don't see what you're looking for, our sales specialists can often find it.

We ship cantilever racking systems across the country, from our multiple U.S. shipping locations. Whether you're in California, Texas, Minnesota or beyond, we've got you covered.

Our extensive stock ships nationwide so you're not limited by location. Want to check lead times or see what's ready to go from your region? Just give us a call at (320) 485-4974.