Warehouse Storage Racks - Warehouse Shelving Systems

Industrial Warehouse Racking & Storage Systems

If you own, work in or manage a business that utilizes industrial heavy duty steel racks and warehouse shelving, you are certainly aware of the importance of choosing the most efficient storage solutions and selecting storage systems from the wide array of choices available in today's marketplace.

Without a doubt, the most common type of heavy duty steel storage systems available today come in the form of component-based rack and metal shelving systems. Many types of heavy duty industrial storage systems incorporate layout and design elements that are geared toward increasing a warehouse's storage density. Layout and design complexity over the past decades have incorporated many innovations in metal shelving unit and rack styles.

Most roll form and structural rack installations now incorporate rack supported wire mesh decking. Wire decks are a highly desirable shelving unit accessory incorporated into warehouse layout and designs and add to both the warehouses safety and functionality. Accessories like wire mesh backs, wire decking, closed tube posts, column protectors and guard rails and safety netting all increase a rack's safety and minimize the maintenance and damage done to any storage systems.

While simple storage cabinets work for storing small items, other specialty storage systems in common use today include bulk racks, drive in racking, rivet shelving, wire shelving, double slotted racks, carton flow & bulk storage racks, coil, cantilever & lumber racks and rack supported structures, to name a few.

After reading about rack warehouse storage systems, you'll be able to make better informed decisions on the various benefits and advantages of several of today's most common warehouse storage solutions.

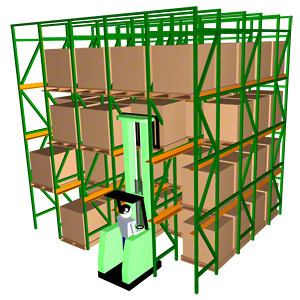

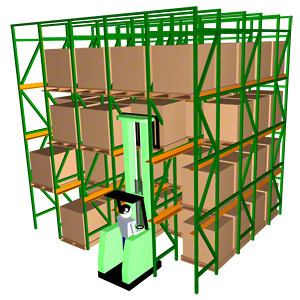

Pallet Racking

Teardrop pallet rack systems or selective rack shelving systems are the most common pallet storage systems and are what is typically thought of for industrial warehouse racks. All warehouse racking for pallet storage is made from component pieces: shelf beams & upright frames and accessories like wire mesh decks (wire shelving), wire deck dividers, safety rack guards and netting, rack protectors, guard panels, pallet supports, end of rack protectors and wall ties.

Pallet Racking »

Carton Flow/Case Flow

The main advantage of carton flow racks (otherwise known as case flow racks) is that merchandise remains better organized and easier to find and/or pick. Carton flow racks can be used either as free standing units or as part of a carton/case flow pick module system, which utilizes carton flow racks with roller track or span track. With carton flow/case flow rack, the product is automatically rotated on a first-in/first-out (FIFO) basis, ensuring the oldest product is used first.

Carton Flow/Case Flow Rack »

Drive-In Pallet Racks

Drive in pallet racks store pallets on a First In/Last Out (FILO) basis. Pallets are loaded and retrieved from the front side of the drive in rack and forklift trucks drive directly into the rack's bays to get to the stored product. The last pallet loaded into the rack becomes the first pallet accessible, creating a more dense and uniform load in a confined storage area. There are no specified lanes between the rows with high density drive in or drive through pallet rack systems.

Drive In Rack »

Pallet Flow Rack

In a pallet flow system, the pallets move from back to front. As they are picked, the next pallet then moves forward. The rack is usually stocked from the back and picked from the front. Lanes of pallet flow rails can be made up of single or double wheel configurations and usually have built-in 'brakes' that slow the pallets as they glide down, allowing for a longer lane. Many of these systems are floor based, providing minimal storage density.

Pallet Flow Rack »

Pushback Pallet Racks

In a pushback pallet rack system, the pallets each sit in a tray that rides along rails in the rack frame itself. The pushback rack's rails are supported on an incline and gravity moves the pallet holding trays along the rails toward the front of the storage rack. When a load is deposited to the front of the rack's storage lane, it will "push back" the previously placed load. This system provides better than average storage density.

Pushback Rack »

Span-Track

Span-Track turns existing static warehouse pallet racking into a dynamic gravity-fed picking system. This type of flow track can be installed right into existing pallet rack or some carton flow beds and allows users to eliminate the need for guide rails. The loads are set on an incline without the need for guide rails or shelf supports. Movement is gravity-based and is traditionally a first in/first out system. Storage density is flexible.

Span-Track »

Warehouse Storage Rack System Brands & Manufacturers

Below is a sampling of different industrial rack & shelving unit brands that we carry here at SJF Material Handling in stock. We specialize in tear drop style racks and stock Interlake Mecalux, Wireway Husky, Steel King, Ridg-u-Rak and other major brands in refurbished and used racks. Don't worry if you are looking for a certain brand and it isn't listed below... we carry all the major brands at SJF Material Handling. If for some reason we don't have it in stock at the moment, our sales professionals are experts at finding the hard-to-find brands you need.

- Amerak

- Atlas

- Blackstone

- Bulldog

- Burtman

- Clymer

- Cogan

- Dexco

- Dexion

- Elite

- EMI

- Excel

- Frazier

- Frick-Gallagher

- Hannibal

- Hiline

- Husky Rack and Wire

- Interlake Mecalux

(New & Old Style)

- Inca

- J-Hook

- Jarke

- Keneco

- Keystone

- Kingway

- Konstant

- Lodi

- Mecalux

- Meco

- Meco-Omaha

- Monarch

- Mirak

- Palmer-Shile

- Paltier

- Penco

- Prest

- Prest Webb Style

- Quick-Pik

- Republic

- RiveTier

- Ridg-U-Rak

- Ross

Warehouse Storage Systems for Pallet Storage

Pallet rack system components for pallet storage include: upright frames, pallet shelving beams, pallet rack shelves, wire decking, rack-back safety panels, column protectors and shelf supports.

Teardrop pallet racks are a type of selective roll formed pallet rack shelving systems and are the most common types of warehouse racking systems used for pallet storage. All storage rack and shelving is made from either structural steel or roll form component parts. They can be sold as pallet rack starter and pallet rack add on kits with everything included or are priced and purchased separately as component upright frames, beams & rack supported wire decks.

To read more about pallet rack storage options, view our helpful guides on pallet racking systems:

Drive In, Drive Through & Pushback Racking

These storage classifications include: drive in rack systems, drive through rack systems and pushback rack systems.

Traditional storage racks and steel shelving allows for many rows of storage and is a great solution for many warehouses. For warehouses that have a large amount of inventory that shifts on a regular basis, drive in racks, drive through racks or push back rack systems are a popular solution you may want to consider.

To read more about drive in racks, including drive through, pushback and other high density warehouse storage racking, view these helpful guides:

Carton Flow & Case Flow Pick Rack (Pick Module FIFO Rack Systems)

These systems include: pick modules, carton and case flow, span-track and pallet flow systems.

Put simply, the main advantage of flow racks is that merchandise remains better organized and easier to find/pick. With carton flow rack, the product is automatically rotated on a first in/first out (FIFO) basis. The concept is simple and effective.

To read more about pick modules, carton flow, case flow, span-track and pallet flow systems, view these helpful guides:

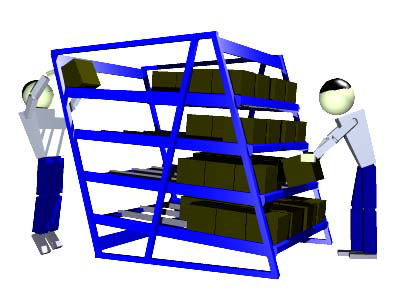

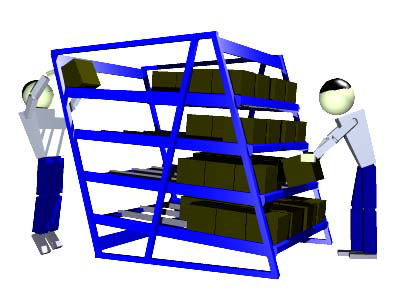

Cantilever Racks (Furniture, Lumber & Pipe Storage Racks)

These storage systems include: lumber racks, auto salvage racks, cantilever supported roofs, pipe racks, steel racks, PVC storage shelving, industrial steel shelving systems, furniture racks, warehouse steel shelving, roll out rack storage systems and more.

Cantilever rack and lumber racks are a very popular industrial warehouse shelving. Lighter versions of this type of industrial warehouse shelving are also known and sold as furniture racks or pipe and sheet steel storage shelving. All of these warehouse storage shelving systems provide an ideal shelving solution for storage of long, bulky materials such as lumber, PVC, sheet metal, bar stock or pipe storage. Furniture rack is a style of lighter duty capacity cantilever racking that can be decked to provide static storage similar to pallet racking.

To read more about cantilever racks, view these helpful guides: